Problem Statement:

One of Matrix’s customers wanted to optimize the design of their agriculture equipment for weight, performance, reliability, and cost. They didn’t know where to start, so they reached out to discuss options.

Methodology and Analysis:

When optimizing a design, one of the first things to do is set a baseline for the current design. Once the baseline is understood, evaluations can be made through hand calculations, finite element analysis (FEA), and other engineering tools to reduce weight and cost while increasing performance and efficiency.

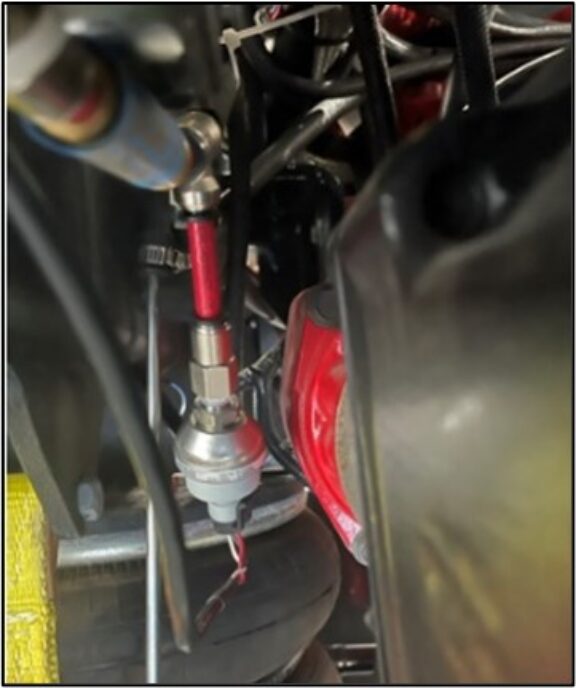

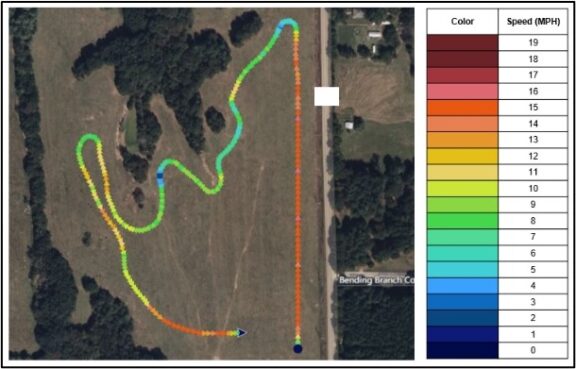

Matrix worked with its customer to develop an on-machine test plan for their current equipment operating in its normal environment. The testing included accelerometers to measure global loading on the machine in multiple chassis locations, pressure transducers to measure hydraulic cylinder pressure, string potentiometers to measure relative motion between chassis components, CAN bus information to read engine parameters, and GPS tracking to correlate the location and speed of the machine during the test events. Matrix arrived at the customer’s location with the equipment in hand, instrumented the machine, and prepped it for testing the following day. The tests were conducted over the next two days, and then Matrix removed all the equipment, returning the machine to its original state with no permanent modifications.

Recommendations and Results:

Once all the data was gathered, the Matrix in-house validation team processed it and compiled it into useful load data, which the customer can use to evaluate their equipment. This data is invaluable because it saves the customer money and reduces their time to market by iterating the design virtually before cutting any material to build a prototype. Matrix prides itself on its collaboration with its customers before the testing, our quick response time, efficient machine setup and testing, and concise packaging of the data.

Matrix Engineering Consultants stands ready to assist you in enhancing your equipment’s performance, reliability, and cost-effectiveness. Our proven product validation and testing and our commitment to clarity and precision ensure that you receive actionable insights and solutions tailored to your specific needs. Don’t hesitate to reach out to us today. Let’s work together to streamline your operations and propel you towards your goals.

Looking for a collaborative partner?

Whether you’re innovating from the ground up or enhancing an existing product, Matrix Engineering is here to guide you. Our team excels in providing dynamic solutions for new developments, improvements, and complex challenges across various industries.