Problem Statement:

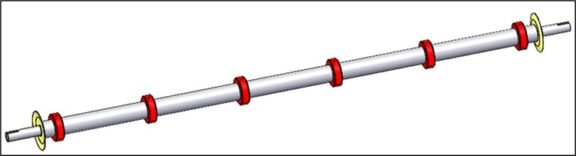

Matrix Engineering was approached to verify and validate the 20-year life expectancy of a client’s 7.5-foot stainless steel shaft system, operating continuously in a dirty water environment. The client aimed to finalize the commercial aspects, including warranty periods, while ensuring the shafts met stringent longevity and performance criteria before market release.

Methodology and Analysis:

Leveraging over 50 years of engineering experience, Matrix comprehensively evaluated the shaft assembly design and the associated manufacturing process controls. The evaluation included a thorough Design Failure Modes and Effects Analysis (DFMEA) in collaborative sessions with cross-functional teams from Matrix, the client, and the manufacturing partner. The DFMEA focused on potential failure modes, including fatigue loading, premature wear, joint slip, and misalignment.

Concurrently, Matrix collaborated with a metallurgical lab and a subject matter expert to inspect the shaft undergoing testing and evaluate the chosen component materials to detect if degradation failure mechanisms such as microcracks occur that could lead to fatigue failure.

Recommendations and Results:

Matrix provided targeted recommendations to enhance the shaft’s longevity and reliability based on the rigorous validation and testing processes. These actions were designed to bolster confidence in the fatigue life predictions and minimize the risk of degradation failures over the required 20-year shaft life period. The client received a final report featuring a detailed risk assessment and strategies for ensuring a successful shaft design. Matrix Engineering stands ready to apply our extensive expertise in product validation and testing to your unique engineering challenges. We invite you to engage with our team of experts to explore tailored, innovative solutions that address your specific needs. Whether you’re in the early stages of design or looking to optimize an existing product, reach out to Matrix to see how we can guide you toward the finish line with confidence.

Looking for a collaborative partner?

Whether you’re innovating from the ground up or enhancing an existing product, Matrix Engineering is here to guide you. Our team excels in providing dynamic solutions for new developments, improvements, and complex challenges across various industries.